Electric Motorcycle Motor

1. What is a motor?

1.1 The motor is a component that converts battery power into mechanical energy to drive the wheels of an electric vehicle to rotate

● The simplest way to understand power is to first know the definition of W, W = wattage, that is, the amount of power consumed per unit time, and the 48v, 60v and 72v we often talk about are the total amount of power consumed, so the higher the wattage, the more power consumed in the same time, and the greater the power of the vehicle (under the same conditions)

● Take 400w, 800w, 1200w, for example, with the same configuration, battery, and 48 voltage:

First of all, under the same riding time, the electric vehicle equipped with a 400w motor will have a longer range, Because the output current is small (driving current is small), the total speed of power consumption is small.

The second is 800w and 1200w. In terms of speed and power, electric vehicles equipped with 1200w motors are faster and more powerful. This is because the higher the wattage, the greater the speed and total amount of power consumption, but at the same time the battery life will be shorter.

● Therefore, under the same V number and configuration, the difference between electric vehicles 400w, 800w and 1200w is in power and speed. The higher the wattage, the stronger the power, the faster the speed, the faster the power consumption, and the shorter the mileage. However, this does not mean that the higher the wattage, the better the electric vehicle. It still depends on the actual needs of itself or the customer.

1.2 The types of two-wheeled electric vehicle motors are mainly divided into: hub motors (commonly used), mid-mounted motors (rarely used, divided by vehicle type)

Electric motorcycle Ordinary motor

Electric motorcycle Mid-mounted motor

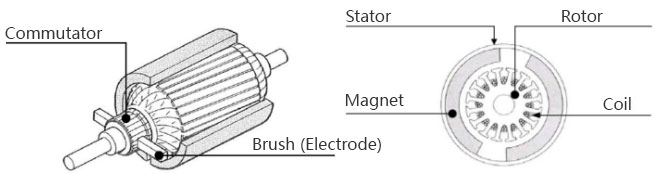

1.2.1 The wheel hub motor structure is mainly divided into: brushed DC motor (basically not used), brushless DC motor (BLDC), permanent magnet synchronous motor (PMSM)

The main difference: whether there are brushes (electrodes)

● Brushless DC motor (BLDC) (commonly used), permanent magnet synchronous motor (PMSM) (rarely used in two-wheeled vehicles)

● The main difference: the two have similar structures, and the following points can be used to distinguish them:

Brushless DC Motor

Brushed DC motor (converting AC to DC is called a commutator)

● Brushless DC motor (BLDC) (commonly used), permanent magnet synchronous motor (PMSM) (rarely used in two-wheeled vehicles)

● The main difference: the two have similar structures, and the following points can be used to distinguish them:

| Project | Permanent magnet synchronous motor | Brushless DC motor |

| Price | Expensive | Cheap |

| Noise | Low | High |

| Performance and efficiency, torque | High | Low, slightly inferior |

| Controller price and control specifications | High | Low, relatively simple |

| Torque pulsation (acceleration jerk) | Low | High |

| Application | High-end models | Mid-range |

● There is no regulation on which is better between permanent magnet synchronous motor and brushless DC motor, it mainly depends on the actual needs of the user or the customer.

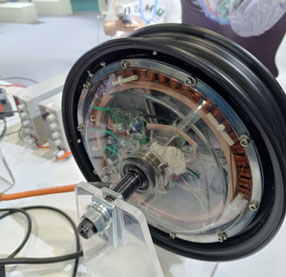

● Hub motors are divided into: ordinary motors, tile motors, water-cooled motors, liquid-cooled motors, and oil-cooled motors.

● Ordinary motor: conventional motor

● Tile motors are divided into: 2nd/3rd/4th/5th generation, 5th generation tile motors are the most expensive, 3000w 5th generation tile Transit motor market price is 2500 yuan, other brands are relatively cheaper.

(The electroplated tile motor has a better appearance)

● Water-cooled/liquid-cooled/oil-cooled motors all add insulating liquid inside the motor to achieve cooling effect and extend the life of the motor. The current technology is not very mature and is prone to leakage and failure.

1.2.2 Mid-Motor: Mid-Non-Gear, Mid-Direct Drive, Mid-Chain/Belt

Ordinary motor

Ordinary motor

Liquid-cooled motor

Oil-cooled motor

● Comparison between hub motor and mid-mounted motor

● Most of the models on the market use hub motors, and mid-mounted motors are less used. It is mainly divided by model and structure. If you want to change the conventional electric motorcycle with hub motor to a mid-mounted motor, you need to change a lot of places, mainly the frame and flat fork, and the price will be expensive.

| Project | Conventional hub motor | Mid-mounted motor |

| Price | Cheap, moderate | Expensive |

| Stability | Moderate | High |

| Efficiency and climbing | Moderate | High |

| Control | Moderate | High |

| Installation and structure | Simple | Complex |

| Noise | Moderate | Relatively large |

| Maintenance cost | Cheap, moderate | High |

| Application | Conventional general purpose | High-end/requires high speed, hill climbing, etc. |

| For motors of the same specifications, the speed and power of the mid-mounted motor will be higher than that of the ordinary hub motor, but similar to the tile hub motor. | ||

2. Several Common Parameters and Specifications of Motors

Several common parameters and specifications of motors: volts, power, size, stator core size, magnet height, speed, torque, example: 72V10 inch 215C40 720R-2000W

● 72V is the motor voltage, which is consistent with the battery controller voltage. The higher the basic voltage, the faster the vehicle speed will be.

● 2000W is the rated power of the motor. There are three types of power, namely rated power, maximum power, and peak power.

Rated power is the power that the motor can run for a long time under rated voltage.

Maximum power is the power that the motor can run for a long time under rated voltage. It is 1.15 times the rated power.

Peak power is the maximum power that the power supply can reach in a short time. It can usually only last for about 30 seconds. It is 1.4 times, 1.5 times or 1.6 times the rated power (if the factory cannot provide peak power, it can be calculated as 1.4 times) 2000W×1.4 times=2800W

● 215 is the stator core size. The larger the size, the greater the current that can pass through, and the greater the motor output power. Conventional 10-inch uses 213 (multi-wire motor) and 215 (single-wire motor), and 12-inch is 260 ; Electric leisure tricycles and other electric tricycles do not have this specification, and use rear axle motors.

● C40 is the height of the magnet, and C is the abbreviation of the magnet. It is also represented by 40H on the market. The larger the magnet, the greater the power and torque, and the better the acceleration performance.

● The magnet of a conventional 350W motor is 18H, 400W is 22H, 500W-650W is 24H, 650W-800W is 27H, 1000W is 30H, and 1200W is 30H-35H. 1500W is 35H-40H, 2000W is 40H, 3000W is 40H-45H, etc. Since the configuration requirements of each car are different, everything is subject to the actual situation.

● 720R is the speed, the unit is rpm, the speed determines how fast a car can go, and it is used with a controller.

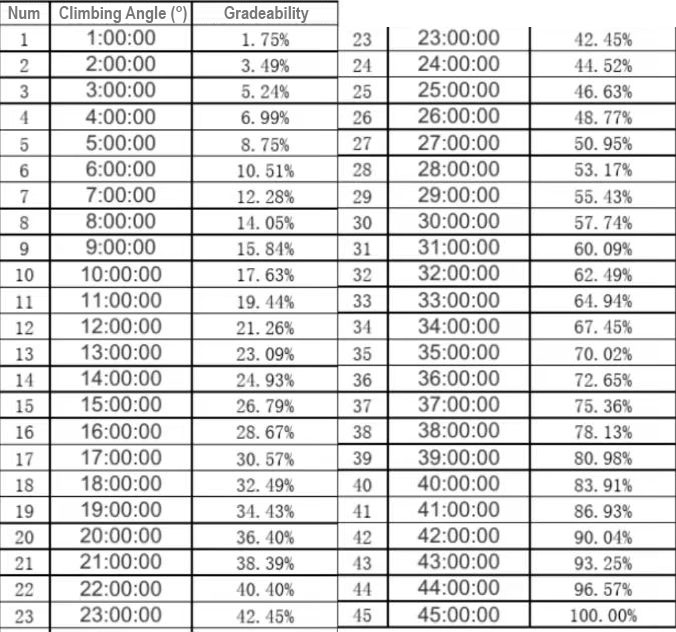

● Torque, the unit is N·m, determines the climbing and power of a car. The greater the torque, the stronger the climbing and power.

Speed and torque are inversely proportional to each other. The faster the speed (vehicle speed), the smaller the torque, and vice versa.

How to calculate speed: For example, the motor speed is 720 rpm (there will be a fluctuation of about 20 rpm), the circumference of a 10-inch tire of a general electric vehicle is 1.3 meters (can be calculated based on data), the controller's overspeed ratio is 110% (the controller's overspeed ratio is generally 110%-115%)

The reference formula for the two-wheel speed is: speed*controller overspeed ratio*60 minutes*tire circumference, that is, (720*110%)*60*1.3=61.776, which is converted to 61km/h. With the load, the speed after landing is about 57km/h (about 3-5km/h less) (the speed is calculated in minutes, so 60 minutes per hour), so the known formula can also be used to reverse the speed.

Torque, in N·m, determines a vehicle's climbing ability and power. The greater the torque, the greater the climbing ability and power.

For example:

● 72V12 inch 2000W/260/C35/750 rpm/torque 127, maximum speed 60km/h, two-person climbing slope of about 17 degrees.

● Need to match the corresponding controller and large-capacity battery-lithium battery is recommended.

● 72V10 inch 2000W/215/C40/720 rpm/torque 125, maximum speed 60km/h, climbing slope of about 15 degrees.

● 72V12 inch 3000W/260/C40/950 rpm/torque 136, maximum speed 70km/h, climbing slope of about 20 degrees.

● Need to match the corresponding controller and large-capacity battery-lithium battery is recommended.

● 10-inch conventional magnetic steel height is only C40, 12-inch conventional is C45, there is no fixed value for torque, which can be adjusted according to customer needs.

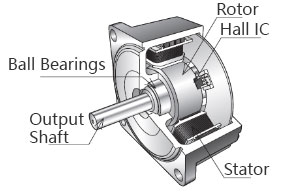

3. Motor Components

● The components of the motor: magnets, coils, Hall sensors, bearings, etc. The greater the motor power, the more magnets are needed (the Hall sensor is the most likely to break)

(A common phenomenon of a broken Hall sensor is that the handlebars and tires get stuck and cannot be turned)

● The function of the Hall sensor: to measure the magnetic field and convert the change in the magnetic field into a signal output (i.e. speed sensing)

Motor composition diagram

Motor windings (coils), bearings, etc.

Stator core

Magnetic steel

Hall

4. Motor Model and Motor Number

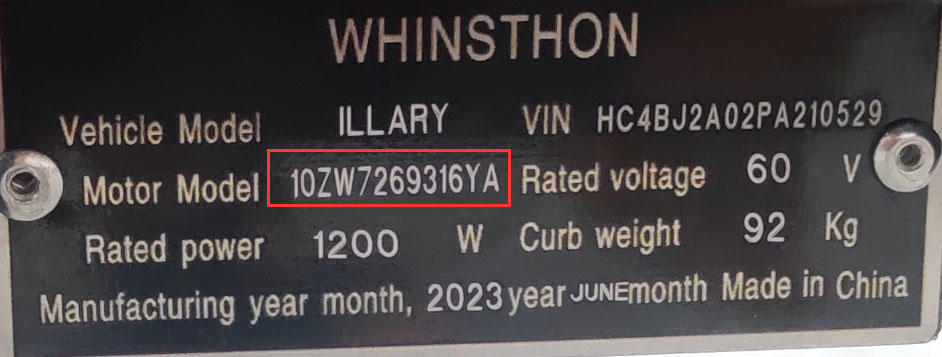

The motor model generally includes the manufacturer, voltage, current, speed, power wattage, model version number, and batch number. Because the manufacturers are different, the arrangement and marking of the numbers are also different. Some motor numbers do not have power wattage, and the number of characters in the electric vehicle motor number is uncertain.

Common motor number coding rules:

● Motor model: WL4820523H18020190032, WL is the manufacturer (Weili), battery 48v, motor 205 series, 23H magnet, produced on February 1, 2018, 90032 is the motor number.

● Motor model: AMTHI60/72 1200W30HB171011798, AMTHI is the manufacturer (Anchi Power Technology), battery universal 60/72, motor wattage 1200W, 30H magnet, produced on October 11, 2017, 798 may be the motor factory number.

● Motor model: JYX968001808241408C30D, JYX is the manufacturer (Jin Yuxing), battery is 96V, motor wattage is 800W, produced on August 24, 2018, 1408C30D may be the manufacturer's unique factory serial number.

● Motor model: SW10 1100566, SW is the abbreviation of the motor manufacturer (Lion King), the factory date is November 10, and 00566 is the natural serial number (motor number).

● Motor model: 10ZW6050315YA, 10 is generally the diameter of the motor, ZW is a brushless DC motor, the battery is 60v, 503 rpm, torque 15, YA is a derived code, YA, YB, YC are used to distinguish different motors with the same performance parameters from the manufacturer.

● Motor number: There is no special requirement, generally it is a pure digital number or the manufacturer's abbreviation + voltage + motor power + production date are printed in front.

Motor model

5. Speed Reference Table

Ordinary motor

Tile motor

Mid-mounted motor

| Ordinary electric motorcycle motor | Tile motor | Mid-mounted motor | Remark |

| 600w--40km/h | 1500w--75-80km/h | 1500w--70-80km/h | Most of the above data are the speeds actually measured by modified cars in Shenzhen, and are used in conjunction with corresponding electronic controls. Except for the Oppein system, the Chaohu system can basically do it, but this refers to pure speed, not climbing power. |

| 800w--50km/h | 2000w--90-100km/h | 2000w--90-100km/h | |

| 1000w--60km/h | 3000w--120-130km/h | 3000w--110-120km/h | |

| 1500w--70km/h | 4000w--130-140km/h | 4000w--120-130km/h | |

| 2000w--80km/h | 5000w--140-150km/h | 5000w--130-140km/h | |

| 3000w--95km/h | 6000w--150-160km/h | 6000w--140-150km/h | |

| 4000w--110km/h | 8000w--180-190km/h | 7000w--150-160km/h | |

| 5000w--120km/h | 10000w--200-220km/h | 8000w--160-170km/h | |

| 6000w--130km/h | 10000w--180-200km/h | ||

| 8000w--150km/h | |||

| 10000w--170km/h |

6. Common Motor Problems

6.1 The motor turns on and off

● The battery voltage will stop and start when it is at the critical undervoltage state.

● This fault will also occur if the battery connector has poor contact.

● The speed control handle wire is about to be disconnected and the brake power-off switch is faulty.

● The motor will stop and start if the power lock is damaged or has poor contact, the line connector is poorly connected, and the components in the controller are not welded firmly.

6.2 When turning the handle, the motor gets stuck and cannot turn

● The common cause is that the motor Hall is broken, which cannot be replaced by ordinary users and requires professionals.

● It may also be that the internal coil group of the motor is burned out.

6.3 Common maintenance

● The motor with any configuration should be used in the corresponding scene, such as climbing. If it is only configured for 15° climbing, long-term forced climbing of a slope of more than 15° will cause damage to the motor.

● The conventional waterproof level of the motor is IPX5, which can withstand water spraying from all directions, but cannot be immersed in water. Therefore, if it is raining heavily and the water is deep, it is not recommended to ride out. One is that there will be a risk of leakage, and the second is that the motor will be unusable if it is flooded.

● Please do not modify it privately. Modifying an incompatible high-current controller will also damage the motor.