Leading Manufacturer for Bicycle Recharge Battery - high quality 1300W 60V 47km/h three wheel electric Cargo tricycle – CYCLEMIX

Leading Manufacturer for Bicycle Recharge Battery - high quality 1300W 60V 47km/h three wheel electric Cargo tricycle – CYCLEMIX Detail:

|

Specification Information |

|

|

Vehicle size |

3080*1180*1400mm |

|

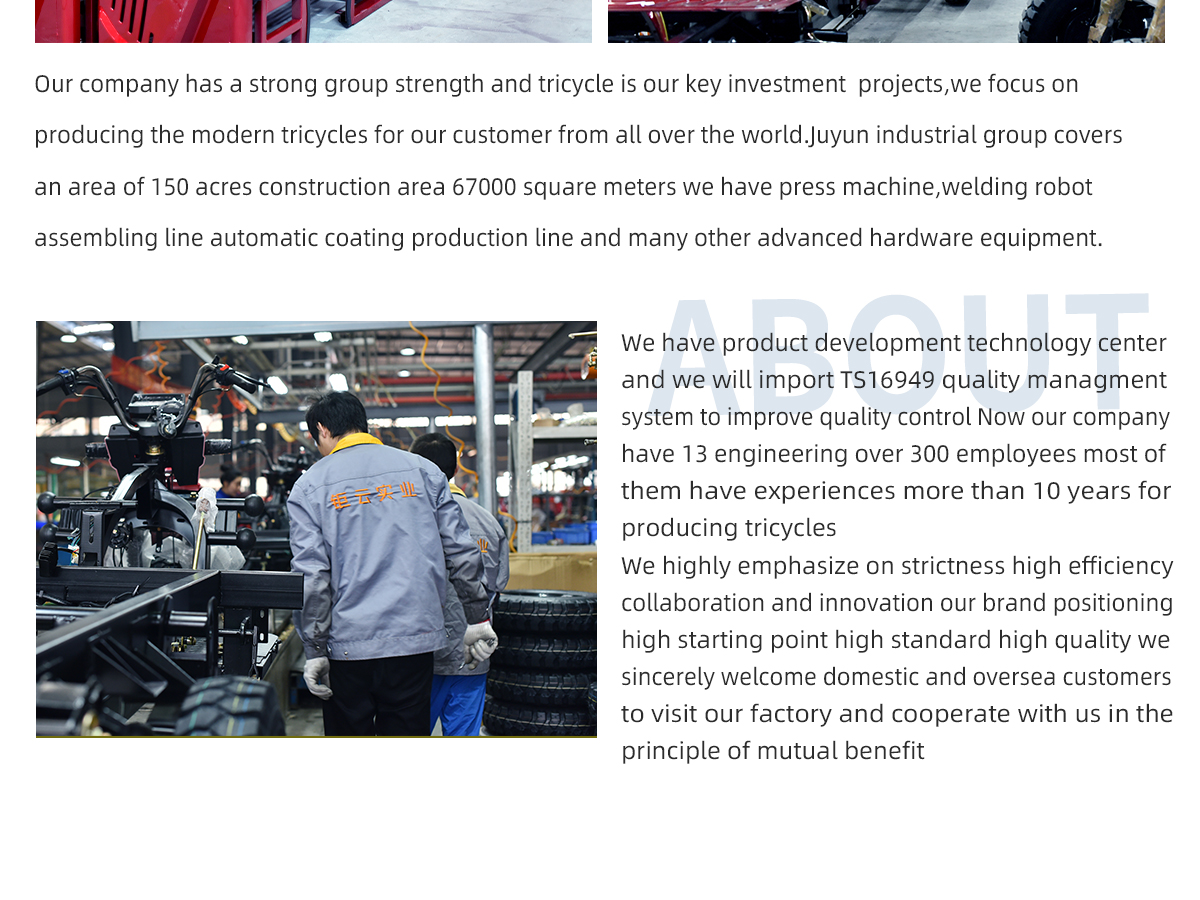

Carriage size |

1600*1100*350mm |

|

Wheelbase |

2110mm |

|

Track width |

960mm |

|

Battery |

60V45A |

|

Full charge range |

50-60km |

|

Controller |

60/72V-24G |

|

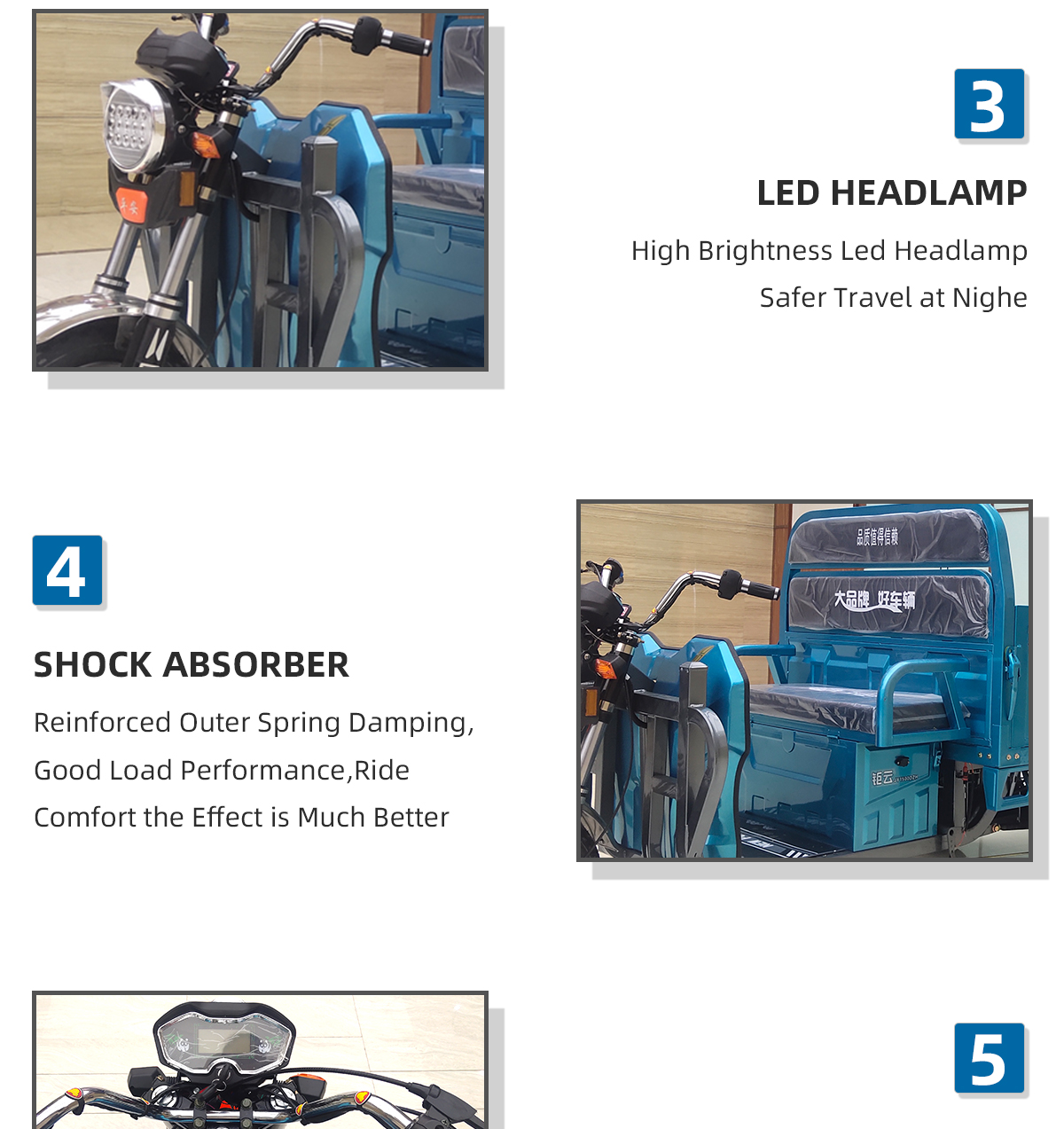

Motor |

1300W 60V (Max Speed 47km/h) |

|

Number of cab passengers |

1 |

|

Rated cargo weight |

500kg |

|

Ground clearance |

180mm |

|

Chassis |

40*60mm chassis |

|

Rear axle assembly |

half floating booster rear axle with 160mm drum brake |

|

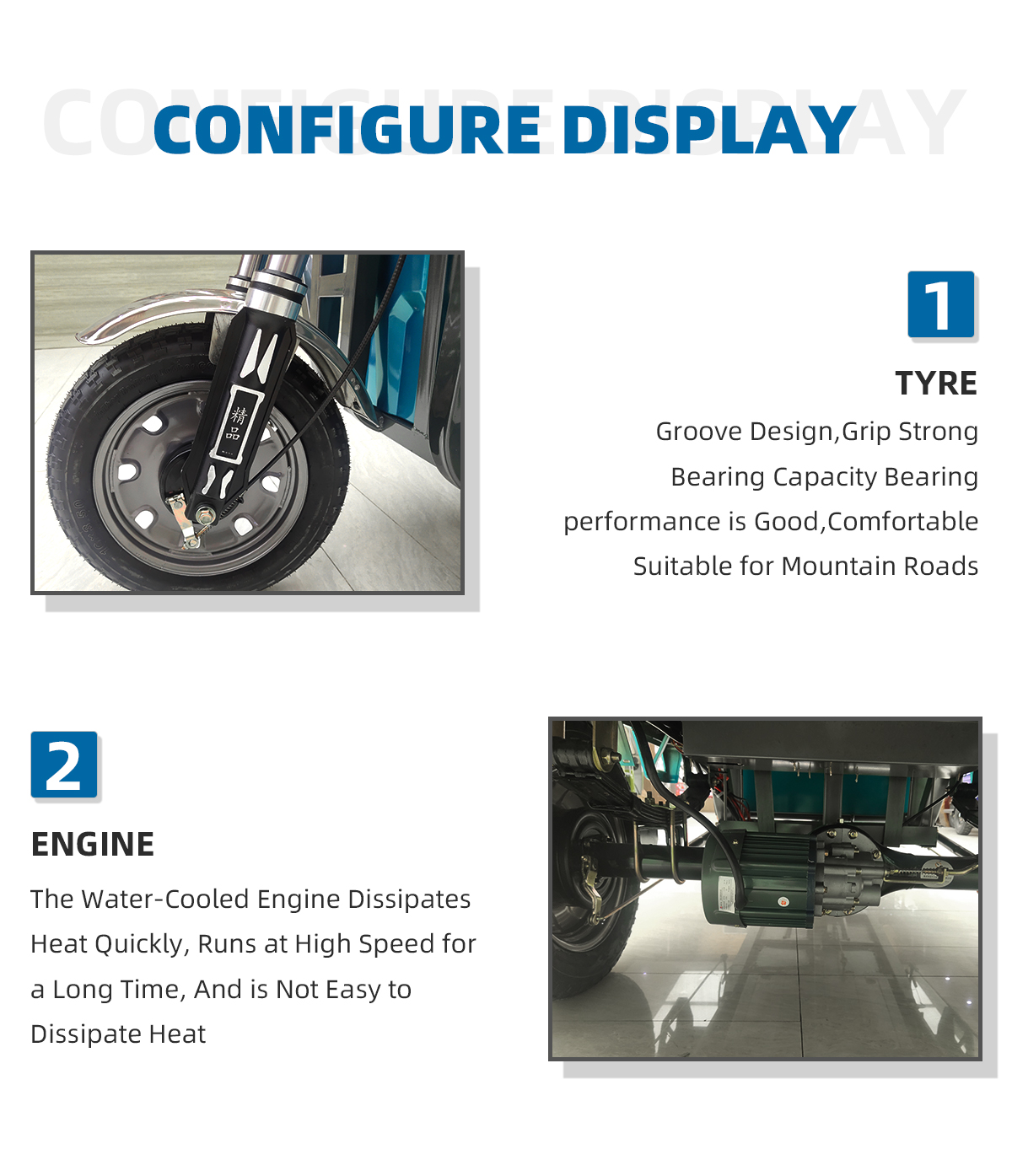

Front damping system |

Ф43 hydraulic shock absorber |

|

Rear damping system |

8 layer Steel plate |

|

Brake system |

front and rear drum brake |

|

Hub |

Steel wheel |

|

Front and Rear tire size |

Front 3.50-12, Rear 4.00-12 |

|

Front bumper |

integrated bumper |

|

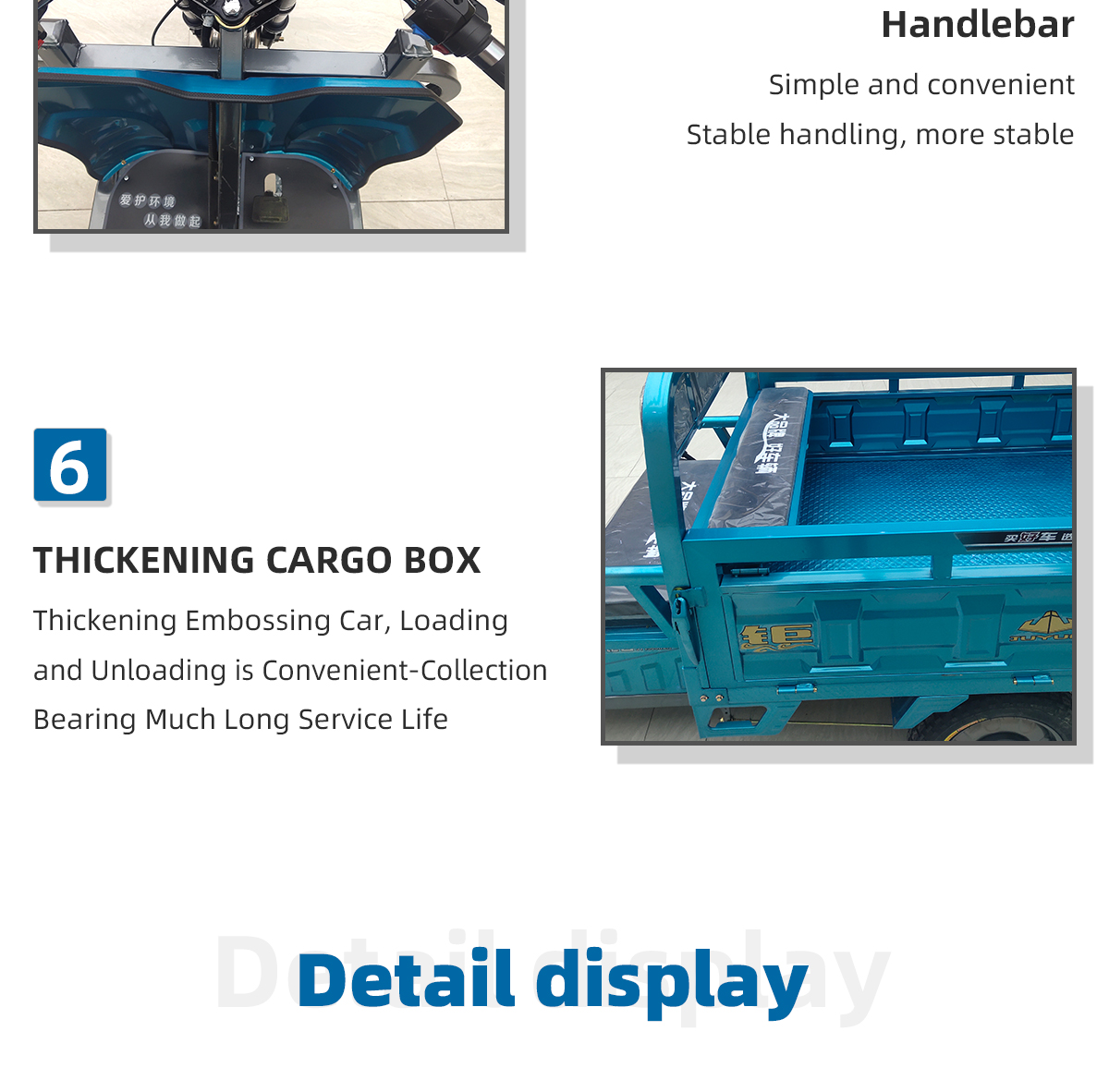

Headlight |

led |

|

Meter |

liquid crystal instrument |

|

Rearview mirror |

rotatable |

|

Seat/backrest |

leather seat |

|

Steering system |

Handlebar |

|

Horn |

front and rear horn |

|

Vehicle weight (excluding battery) |

210kg |

|

Climbing angle |

25° |

|

Parking brake system |

hand brake |

|

Drive mode |

rear drive |

|

Color |

red/blue/green/white/black/orange |

Product detail pictures:

Related Product Guide:

Leading Manufacturer for Bicycle Recharge Battery - high quality 1300W 60V 47km/h three wheel electric Cargo tricycle – CYCLEMIX , The product will supply to all over the world, such as: , , ,

1. Electric bicycle frame fatigue test

The electric bicycle frame fatigue test is a test method used to evaluate the durability and strength of the electric bicycle frame in long-term use. The test simulates the stress and load of the frame under different conditions to ensure that it can maintain good performance and safety in actual use.

2. Electric bicycle shock absorption fatigue test

Electric bicycle shock absorber fatigue test is an important test to evaluate the durability and performance of shock absorbers under long-term use. This test simulates the stress and load of shock absorbers under different riding conditions, helping manufacturers ensure the quality and safety of their products.

3. Electric bicycle rain test

The electric bicycle rain test is a test method used to evaluate the waterproof performance and durability of electric bicycles in rainy environments. This test simulates the conditions encountered by electric bicycles when riding in the rain, ensuring that their electrical components and structures can work properly under adverse weather conditions.