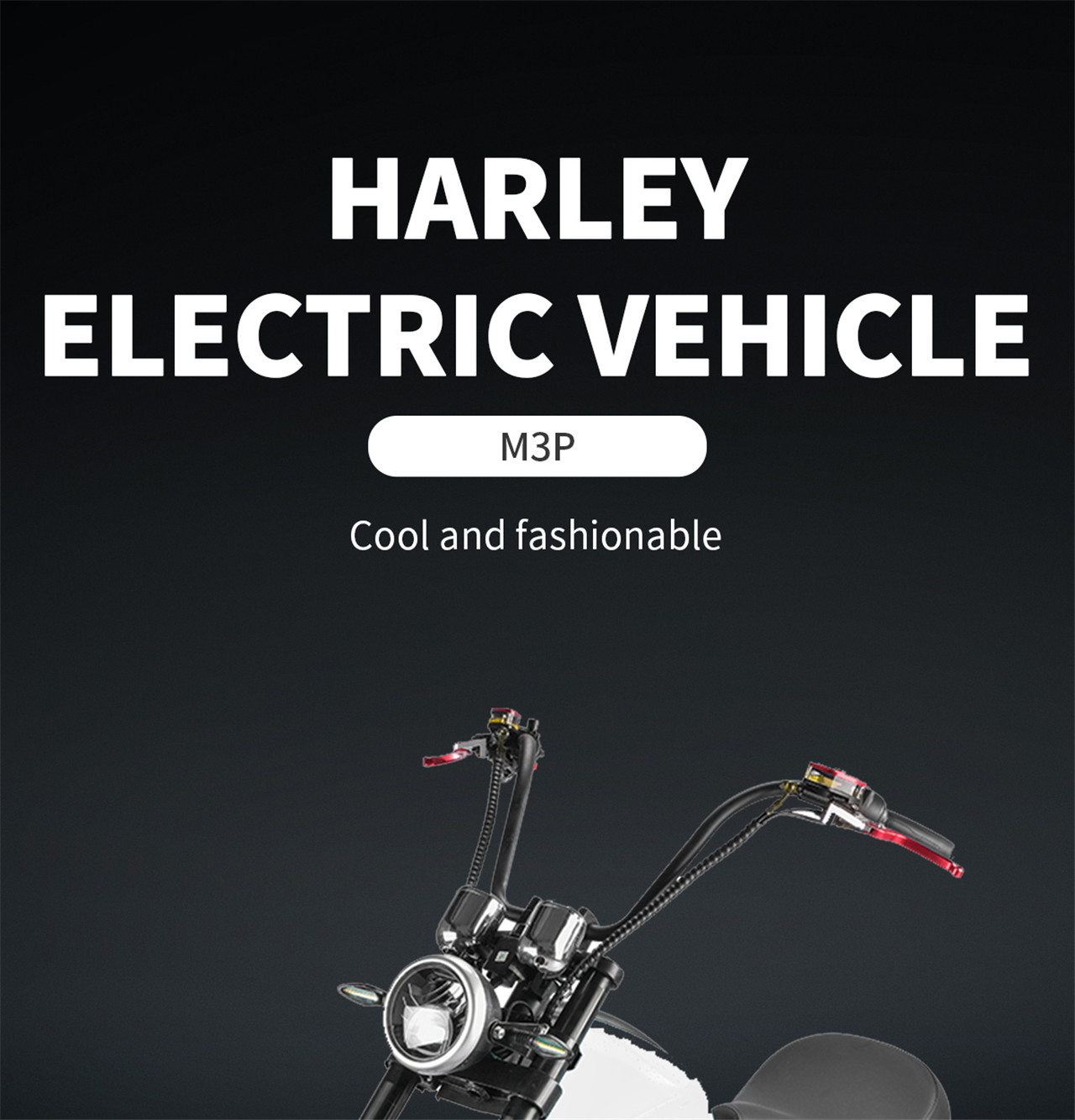

EEC 60V 1500-3000W 12 inch aluminum wheels harley electric scooter

| Frame material | seamless steel pipe | ||||||||

| Wheels and tires | 12-inch aluminum wheels | ||||||||

| Packing size | 1880*375*770mm | ||||||||

| Gross weight/net weight | 87kg/76KG | ||||||||

| Maximum speed | 60km/h | ||||||||

| Maximum load | 200kg | ||||||||

| Cruising range | 30/60/75km | ||||||||

| Climbing ability | 30° | ||||||||

| Acceleration method | turn the handle to accelerate | ||||||||

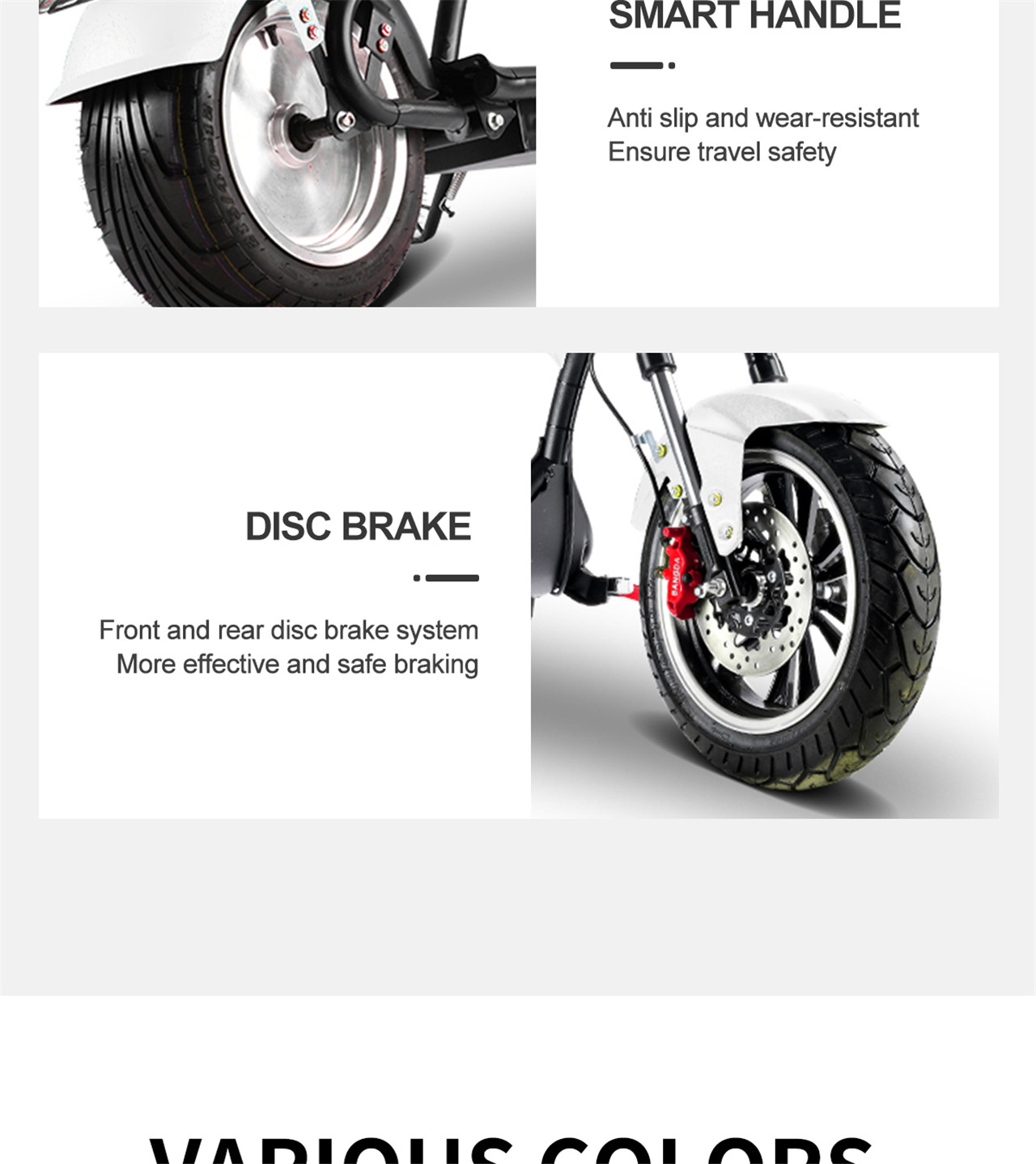

| Braking method | Front and rear hydraulic disc brakes | ||||||||

| Motor power | 60V1500-3000W | ||||||||

| Charging time | Aluminum shell 5A charger | ||||||||

| Packing size | 1880*375*770mm | ||||||||

1. Electric bicycle frame fatigue test

The electric bicycle frame fatigue test is a test method used to evaluate the durability and strength of the electric bicycle frame in long-term use. The test simulates the stress and load of the frame under different conditions to ensure that it can maintain good performance and safety in actual use.

2. Electric bicycle shock absorption fatigue test

Electric bicycle shock absorber fatigue test is an important test to evaluate the durability and performance of shock absorbers under long-term use. This test simulates the stress and load of shock absorbers under different riding conditions, helping manufacturers ensure the quality and safety of their products.

3. Electric bicycle rain test

The electric bicycle rain test is a test method used to evaluate the waterproof performance and durability of electric bicycles in rainy environments. This test simulates the conditions encountered by electric bicycles when riding in the rain, ensuring that their electrical components and structures can work properly under adverse weather conditions.

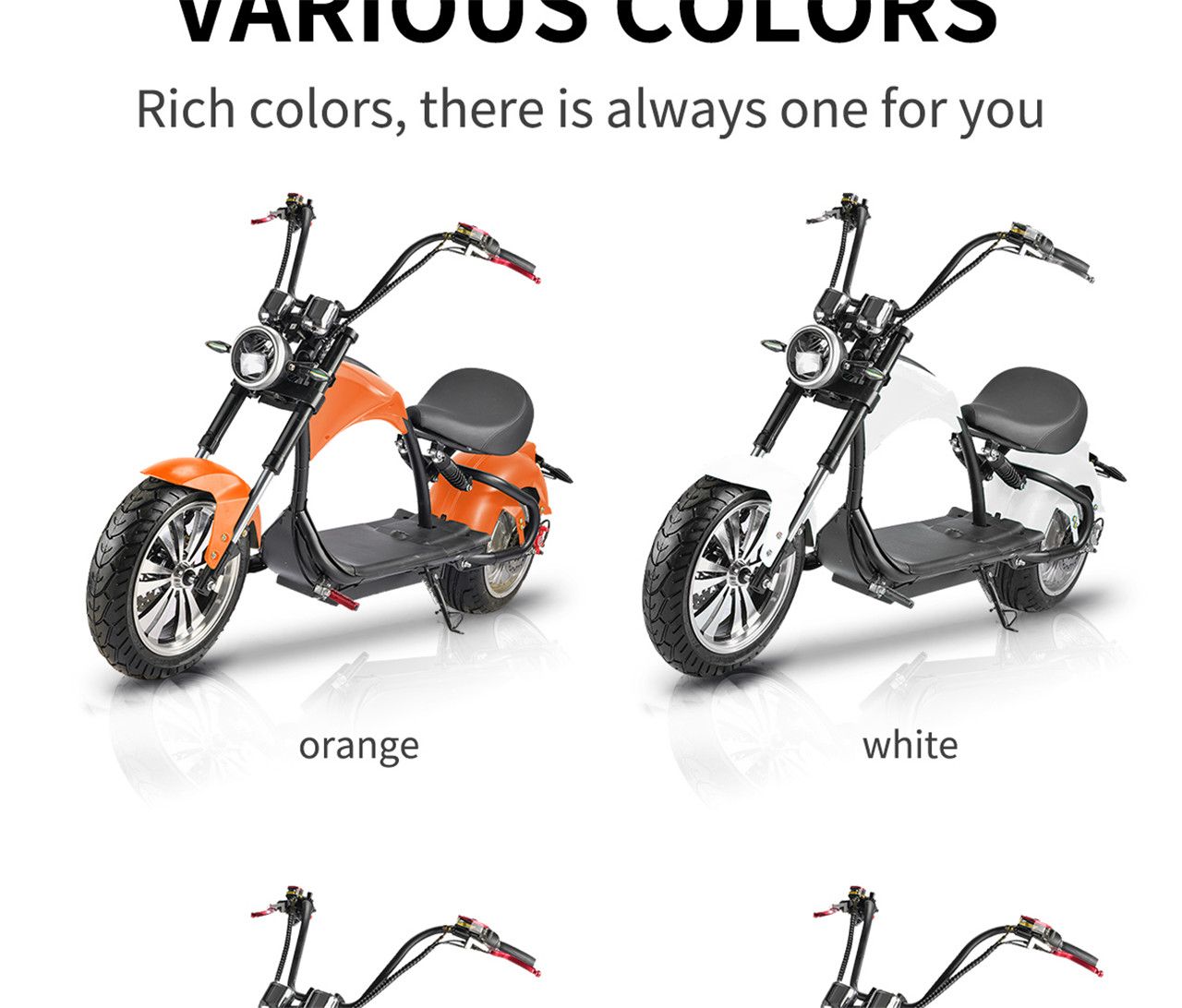

Q: Which colors will be available?

A: Normally, we will introduce the most popular colors to customers. And we are able to make colors according to customer’s demands.

Q: Can I use my logo on the product?

A: Yes, we can make the customers’ logo on the motorcycle.

Q: What is your packing?

A: CKD, SKD and CUB packing. Also can provide customized package as customer’s request

Q: What is quality control?

A: 1.Raw materials will be tested with instruments before they are put into storage

2. Production line manufacturing can reduce the failure rate

3.Full inspection instead of random inspection before packing