1800w 60v 3 Wheel Electric Tricycle For Cargo And Passenger

|

Specification Information |

|

|

Vehicle size |

3080*1180*1400mm |

|

Carriage size |

1600*1100*350mm |

|

Wheelbase |

2110mm |

|

Track width |

960mm |

|

Battery |

60V70A |

|

Full charge range |

80-90km |

|

Controller |

60/72V- 36G |

|

Motor |

1800W 60V (Max Speed 40km/h) |

|

Number of cab passengers |

1 |

|

Rated cargo weight |

800kg |

|

Ground clearance |

180mm |

|

Chassis |

40*60mm chassis |

|

Rear axle assembly |

half floating rear axle with 220mm drum brake |

|

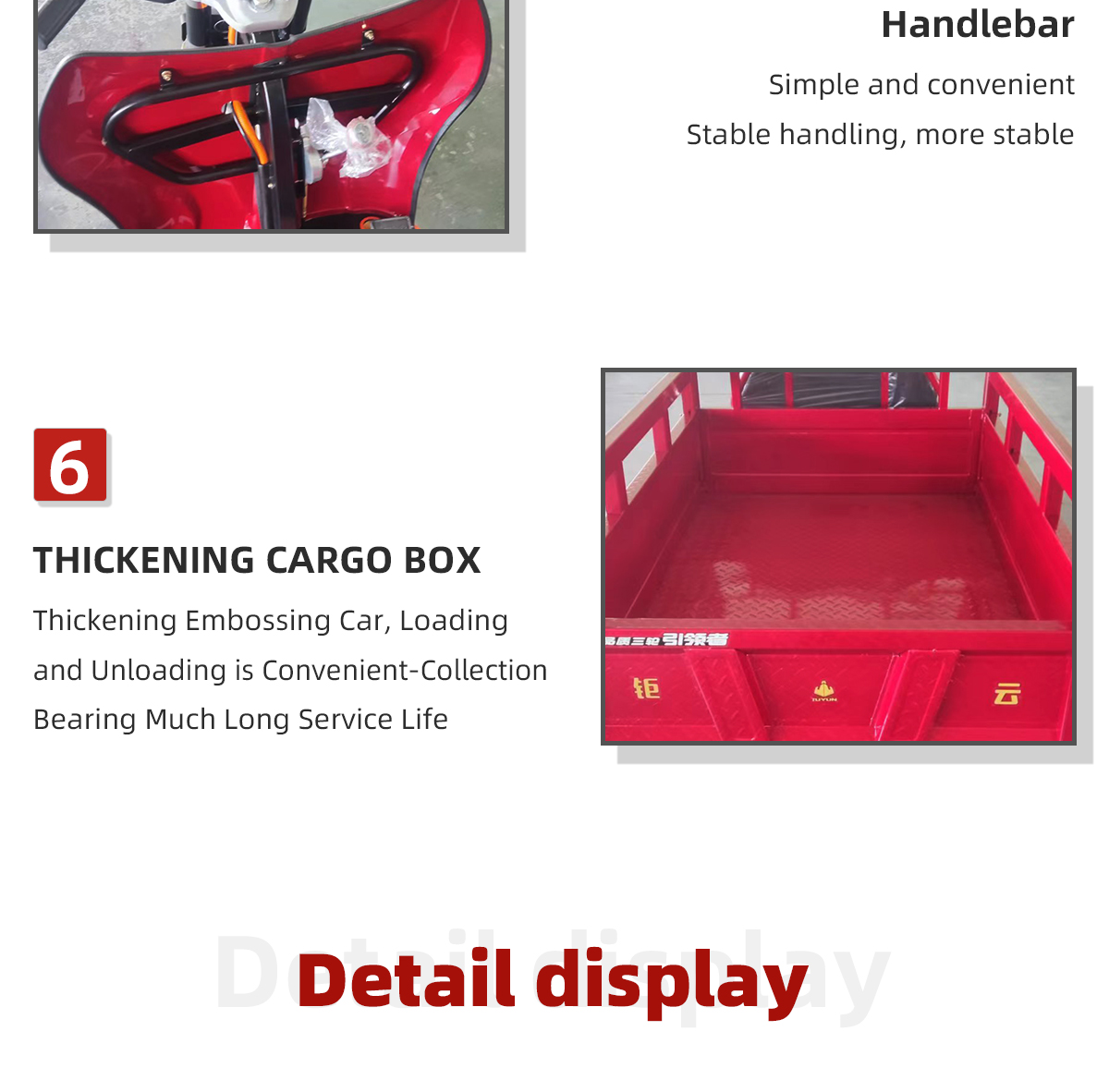

Front damping system |

Ф43 hydraulic shock absorber |

|

Rear damping system |

5 layer Steel plate |

|

Brake system |

front and rear drum brake |

|

Hub |

Steel wheel |

|

Front and Rear tire size |

Front 4.00-12, Rear 4.00-12 |

|

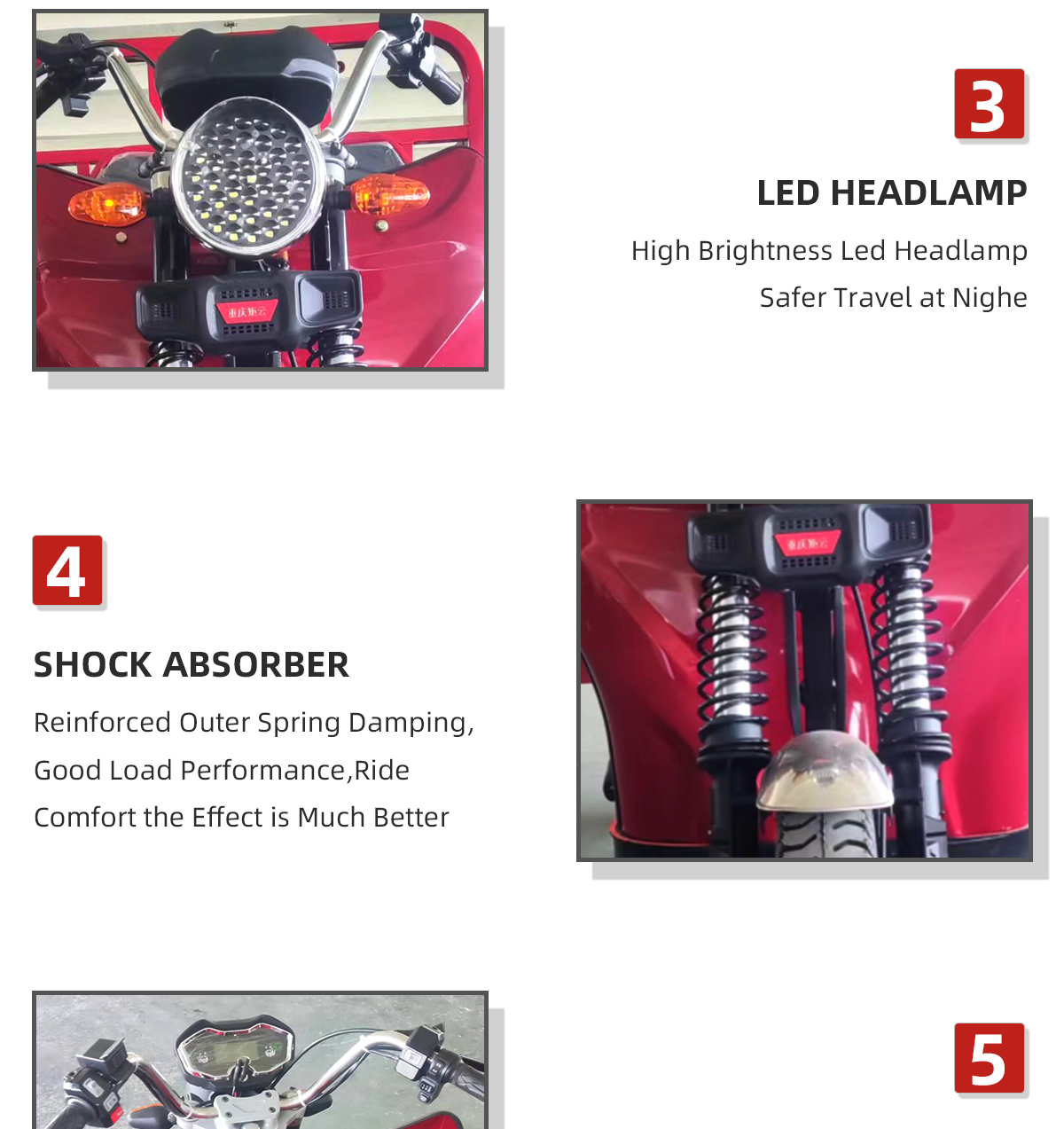

Headlight |

led |

|

Meter |

liquid crystal instrument |

|

Rearview mirror |

rotatable |

|

Seat / backrest |

leather seat |

|

Steering system |

Handlebar |

|

Horn |

front and rear horn |

|

Vehicle weight (excluding battery) |

260kg |

|

Climbing angle |

25° |

|

Parking brake system |

hand brake |

|

Drive mode |

rear drive |

1. Electric bicycle frame fatigue test

The electric bicycle frame fatigue test is a test method used to evaluate the durability and strength of the electric bicycle frame in long-term use. The test simulates the stress and load of the frame under different conditions to ensure that it can maintain good performance and safety in actual use.

2. Electric bicycle shock absorption fatigue test

Electric bicycle shock absorber fatigue test is an important test to evaluate the durability and performance of shock absorbers under long-term use. This test simulates the stress and load of shock absorbers under different riding conditions, helping manufacturers ensure the quality and safety of their products.

3. Electric bicycle rain test

The electric bicycle rain test is a test method used to evaluate the waterproof performance and durability of electric bicycles in rainy environments. This test simulates the conditions encountered by electric bicycles when riding in the rain, ensuring that their electrical components and structures can work properly under adverse weather conditions.

Q:How does your factory do regarding the quality control?

A:Quality is priority. We always attach great importance to quality control from the very beginning to the end of the production.

Every product will be fully assembled and 100% tested before packing and shipping.

Q:why should you buy from us not from other suppliers?

A: We are dedicated in designing and manufacturing the 2 wheel, 3 wheel and 4 wheel electric cars in accordance with Europe EEC L1e-L7e homologation.

Q:What is your sample policy?

A: We can supply the sample if we have ready parts in stock, but the customers have to pay the sample cost and the courier cost.

Q:What can you do regarding long-term cooperation?

A:1. We could keep stable and consistent quality and reasonable price to ensure our customers benefit;

2. We know how to do business with foreign customers and what we should do to make our customers happy time.